AIR INTAKE OF AN ENGINE: HOW DOES IT WORK?

For a heat engine to ignite, two essential components are necessary: fuel and an oxidizing agent. In this discussion, we will concentrate on examining how the oxidizer, specifically the oxygen from the air, is delivered to the engine.

Air supply: which path does the oxidizer travel?

The air that is sent to the combustion chamber must pass through a circuit on which there are several determining elements, let’s see them now.

1)Air filter

The first thing that the oxidizer admitted to an engine will encounter is the air filter. The latter is responsible for trapping and retaining as many particles as possible to prevent them from damaging the bowels of the engine (combustion chamber). However, there are several settings / sizes of air filters. The more particles a filter will retain, the less it will let air pass easily: this will slightly reduce the power of the engine (which then breathes a little less well) but it will improve the quality of the air which will enter the engine (less parasitic particles). Conversely, a filter that lets in a lot of air (high flow rate) will improve performance but will allow more particles to enter.

It must be changed regularly because it ends up clogging.

2) Air flow meter

On modern engines, this sensor is used to tell the engine control unit the mass of air entering the engine and its temperature. With these parameters in hand, the computer will know how to control the injection and the throttle valve (petrol) so that combustion is perfectly regulated (richness of the air / fuel mixture).

By clogging it no longer sends the right data to the computer: loss of power to the key.

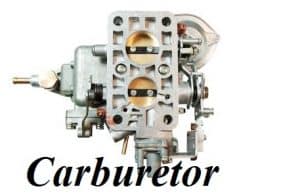

3) Carburetor (old petrol engine)

On older petrol engines (until the 90s), there is a carburetor which has two functions: mixing the fuel with air and modulating the air flow entering the engine (accelerating). Its adjustment could sometimes be tedious … Today it is the calculator which doses the air / fuel mixture itself (your engine therefore now adapts itself on its own to changes in atmospheric conditions: mountain, plain etc.).

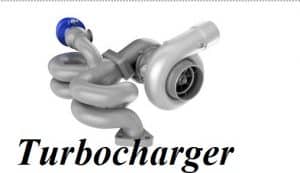

4) Turbocharger (optional)

Designed to increase engine performance, it will send more air into the engine. Instead of being limited to the natural aspiration of the engine (by the movements of the pistons), we add a system which will also “blow” a lot of air inside. In this way, we can then also increase the quantity of fuel and therefore the combustion (more intense combustion = more power). A turbo works well in high revs because it is powered by the exhaust flow (more important at high revs). A compressor (supercharger) is identical to the turbo except that it is powered by the force of the engine (suddenly it rotates less quickly but works earlier in the turns: the torque at low speed is better).

There are static turbos and variable geometry turbos.

5) Exchanger / Intercooler (optional)

In the case of a turbo engine, we make sure to cool the air sent by the compressor (the turbo therefore) because the latter was slightly heated during its compression (a compressed gas naturally heats). But above all, cooling the air allows more to be inserted into the combustion chamber (a cold gas takes up less space than a hot gas). This is therefore an exchanger: the air to be cooled is passed through a compartment which is glued to another colder one (which is itself cooled by fresh outside air [air / air] or with water [air / water])

6) Throttle body (petrol without carburetor)

Petrol engines work thanks to a very precise mixture between air and fuel, so a butterfly flap is needed to regulate the air entering the engine. Diesel running in excess air does not need it (modern diesel engines have one but for other and almost anecdotal reasons).

When accelerating with a petrol engine, you have to measure both air and fuel: stoichiometric mixture with a ratio of 1 / 14.7 (fuel / air). So in low revs where little fuel is needed (because we want a thread of gas), we are forced to filter the amount of air that arrives so that it is not in excess. On the other hand, when you accelerate with a diesel you only vary the injection of fuel into the combustion chambers (on the versions with turbo, the supercharging also starts to send more air into the cylinders).

7) intake manifold

The intake manifold is one of the very last steps in the path taken by the intake air. It is a question here of distributing the air which arrives in each cylinder: the way is then divided into several ways (depends on the number of cylinders in the engine). A pressure and temperature sensor allows the computer to control the engine more finely. The pressure in the manifold is low on low-load petrol (throttle not fully open, low acceleration) while it is always positive (> 1 bar) on diesels. See more in the article below to understand.

On gasoline with direct injection, the injectors are placed on the manifold to vaporize the fuel there. There are then single point (older) and multi-point versions: see here.

Some elements are connected to the intake manifold:

EGR valve: an EGR valve is present on modern engines, it allows part of the gases to be returned to the intake manifold so that they pass back into the cylinders (reduces pollution: NOx thanks to the cooling of the less oxygen).

Breather: oil vapors from the crankcase are returned to the intake

8) Inlet valve

This is the last step, the air enters the engine through a small door called the intake valve which opens and closes continuously (according to the 6.4 powerstroke cycle).

How does the calculator do the right mixing?

The engine computer allows you to dose all the “ingredients” fairly thanks to the information provided by the various sensors / probes. The flow meter indicates the incoming air mass and its temperature. The pressure sensor in the intake manifold makes it possible to know the pressure of the turbocharging by modulating the latter thanks to the wastegate. The lambda probe in the exhaust allows you to see what the result of the mixture gave by studying the capacity of the exhaust gases.